- Car History Reports

- VIN Search

- VIN Decoders

- Lemon Law Info

- Auto Recall

- VIN Information

- Understanding VIN

- VIN Details

- VIN History

- State Transportation Web Sites

- VIN Europe

- VIN Code Law

- VIN Glossary

- VIN and Auto Theft

- Deter Auto Theft

- VIN and Flood Damage

- Department of Motor Vehicles (DMV) - by State

- About Us

Don't have your VIN Number?

Click here to send yourself a reminder.

Click here to send yourself a reminder.

Just What Is a Car Recall? Car Safety Recall Definition - A safety recall is an automotive manufacturer's way of notifying vehicle customers that their product has a flaw. The automobile problem is serious enough that if you do not correct the flaw your and/or your passengers' safety could be at risk. Generally recalls are initiated by the US Government, but sometimes individual car manufacturers will pre-emptively initiate a recall.

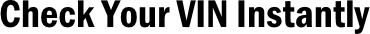

Where Do I Find My VIN (Vehicle Identification Number)? Look on the lower left of your car’s windshield for your 17-digit Vehicle Identification Number (VIN). Your VIN is also located on your car’s registration card, and it may be shown on your insurance card.

Auto Tip - How Do I Find Out If My Vehicle Has A Recall? ==> An easy way to determine if you have an active car recall is to just enter your VIN number at the top of this page and CarFax will report if there are any issues at all with your vehicle.

Dodge CB400

-

DODGE CB400 1976

DUE TO A COMBINATION OF DISC BRAKE PAD WEAR AND TURN STOP WEAR ON CERTAIN VEHICLES, THERE MAY BE AN INCREASE IN BRAKE PEDAL TRAVEL AND A REDUCTION IN FRONT BRAKING EFFECTIVENESS FOLLOWING A FULL TURN. ALSO, A FRAME CRACK COULD DEVELOP AND COULD EXTEND THROUGH ALL OR MOST OF THE RAIL SECTION.

-

DODGE CB400 1975

DUE TO A COMBINATION OF DISC BRAKE PAD WEAR AND TURN STOP WEAR ON CERTAIN VEHICLES, THERE MAY BE AN INCREASE IN BRAKE PEDAL TRAVEL AND A REDUCTION IN FRONT BRAKING EFFECTIVENESS FOLLOWING A FULL TURN. ALSO, A FRAME CRACK COULD DEVELOP AND COULD EXTEND THROUGH ALL OR MOST OF THE RAIL SECTION.

-

DODGE CB400 1974

DUE TO A COMBINATION OF DISC BRAKE PAD WEAR AND TURN STOP WEAR ON CERTAIN VEHICLES, THERE MAY BE AN INCREASE IN BRAKE PEDAL TRAVEL AND A REDUCTION IN FRONT BRAKING EFFECTIVENESS FOLLOWING A FULL TURN. ALSO, A FRAME CRACK COULD DEVELOP AND COULD EXTEND THROUGH ALL OR MOST OF THE RAIL SECTION.

-

DODGE CB400 1973

DUE TO A COMBINATION OF DISC BRAKE PAD WEAR AND TURN STOP WEAR ON CERTAIN VEHICLES, THERE MAY BE AN INCREASE IN BRAKE PEDAL TRAVEL AND A REDUCTION IN FRONT BRAKING EFFECTIVENESS FOLLOWING A FULL TURN. ALSO, A FRAME CRACK COULD DEVELOP AND COULD EXTEND THROUGH ALL OR MOST OF THE RAIL SECTION.

-

DODGE CB400 1977

DUE TO A COMBINATION OF DISC BRAKE PAD WEAR AND TURN STOP WEAR ON CERTAIN VEHICLES, THERE MAY BE AN INCREASE IN BRAKE PEDAL TRAVEL AND A REDUCTION IN FRONT BRAKING EFFECTIVENESS FOLLOWING A FULL TURN. ALSO, A FRAME CRACK COULD DEVELOP AND COULD EXTEND THROUGH ALL OR MOST OF THE RAIL SECTION.

-

DODGE CB400 1976

THE FRONT RAIL EXTENSION MAY EXPERIENCE FATIGUE CRACKING NEAR THE AREA WHERE THE POWER STEERING GEAR ATTACHES TO THE FRAME. IF THE CRACK PROGRESSES THROUGH MOST OR ALL OF THE RAIL SECTION, STEERING SYSTEM FREE PLAY ACCOMPANIED BY METALLIC RATTLE NOISE WILL BE EXPERIENCED.

-

DODGE CB400 1975

THE FRONT RAIL EXTENSION MAY EXPERIENCE FATIGUE CRACKING NEAR THE AREA WHERE THE POWER STEERING GEAR ATTACHES TO THE FRAME. IF THE CRACK PROGRESSES THROUGH MOST OR ALL OF THE RAIL SECTION, STEERING SYSTEM FREE PLAY ACCOMPANIED BY METALLIC RATTLE NOISE WILL BE EXPERIENCED.

-

DODGE CB400 1974

THE FRONT RAIL EXTENSION MAY EXPERIENCE FATIGUE CRACKING NEAR THE AREA WHERE THE POWER STEERING GEAR ATTACHES TO THE FRAME. IF THE CRACK PROGRESSES THROUGH MOST OR ALL OF THE RAIL SECTION, STEERING SYSTEM FREE PLAY ACCOMPANIED BY METALLIC RATTLE NOISE WILL BE EXPERIENCED.

-

DODGE CB400 1972

THE FRONT RAIL EXTENSION MAY EXPERIENCE FATIGUE CRACKING NEAR THE AREA WHERE THE POWER STEERING GEAR ATTACHES TO THE FRAME. IF THE CRACK PROGRESSES THROUGH MOST OR ALL OF THE RAIL SECTION, STEERING SYSTEM FREE PLAY ACCOMPANIED BY METALLIC RATTLE NOISE WILL BE EXPERIENCED.

-

DODGE CB400 1971

THE FRONT RAIL EXTENSION MAY EXPERIENCE FATIGUE CRACKING NEAR THE AREA WHERE THE POWER STEERING GEAR ATTACHES TO THE FRAME. IF THE CRACK PROGRESSES THROUGH MOST OR ALL OF THE RAIL SECTION, STEERING SYSTEM FREE PLAY ACCOMPANIED BY METALLIC RATTLE NOISE WILL BE EXPERIENCED.

-

DODGE CB400 1973

THE FRONT RAIL EXTENSION MAY EXPERIENCE FATIGUE CRACKING NEAR THE AREA WHERE THE POWER STEERING GEAR ATTACHES TO THE FRAME. IF THE CRACK PROGRESSES THROUGH MOST OR ALL OF THE RAIL SECTION, STEERING SYSTEM FREE PLAY ACCOMPANIED BY METALLIC RATTLE NOISE WILL BE EXPERIENCED.

-

DODGE CB400 1978

THE FRONT RAIL EXTENSION MAY EXPERIENCE FATIGUE CRACKING NEAR THE AREA WHERE THE POWER STEERING GEAR ATTACHES TO THE FRAME. IF THE CRACK PROGRESSES THROUGH MOST OR ALL OF THE RAIL SECTION, STEERING SYSTEM FREE PLAY ACCOMPANIED BY METALLIC RATTLE NOISE WILL BE EXPERIENCED.

-

DODGE CB400 1977

THE FRONT RAIL EXTENSION MAY EXPERIENCE FATIGUE CRACKING NEAR THE AREA WHERE THE POWER STEERING GEAR ATTACHES TO THE FRAME. IF THE CRACK PROGRESSES THROUGH MOST OR ALL OF THE RAIL SECTION, STEERING SYSTEM FREE PLAY ACCOMPANIED BY METALLIC RATTLE NOISE WILL BE EXPERIENCED.

-

DODGE CB400 1979

CONDENSATE WATER MAY ACCUMULATE IN THE AIR CONDITIONING BLOWER HOUSING; THERE IS A HIGH PROBABILITY THAT THIS WATER WILL CAUSE THE BLOWER MOTOR TO FAIL. BLOWER MOTOR FAILURE WOULD DISABLE THE AIR CONDTIONING UNIT AND THERE WOULD BE NO WAY TO DEFROST OR DEFOG THE WINDSHIELD.

-

DODGE CB400 1978

INCORRECT STEERING LINKAGE COMPONENTS MAY HAVE BEEN INSTALLED ON THE INVOLVED VEHICLES. THESE VEHICLES WERE ASSEMBLED WITH LIGHT DUTY STEERING LINKAGE TIE ROD AND CENTER LINK ASSEMBLIES IN PLACE OF THE SPECIFIED HEAVY DUTY COMPONENTS. THESE LIGHT DUTY COMPONENTS ARE NOT COMPATIBLE FOR ATTACHMENT TO THE HEAVY DUTY KNUCKLE ARMS, RESULTING IN AN INFLEXIBLE (NO BALL JOINT MOVEMENT) ATTACHMENT OF THE TIE ROD TO KNUCKLE ARM. THIS COULD, EVENTUALLY, RESULT IN FATIGUE FAILURE OF THAT ATTACHMENT ON ONE OF THE COMPONENTS.

-

DODGE CB400 1979

INCORRECT STEERING LINKAGE COMPONENTS MAY HAVE BEEN INSTALLED ON THE INVOLVED VEHICLES. THESE VEHICLES WERE ASSEMBLED WITH LIGHT DUTY STEERING LINKAGE TIE ROD AND CENTER LINK ASSEMBLIES IN PLACE OF THE SPECIFIED HEAVY DUTY COMPONENTS. THESE LIGHT DUTY COMPONENTS ARE NOT COMPATIBLE FOR ATTACHMENT TO THE HEAVY DUTY KNUCKLE ARMS, RESULTING IN AN INFLEXIBLE (NO BALL JOINT MOVEMENT) ATTACHMENT OF THE TIE ROD TO KNUCKLE ARM. THIS COULD, EVENTUALLY, RESULT IN FATIGUE FAILURE OF THAT ATTACHMENT ON ONE OF THE COMPONENTS.